$63/hr

$63/hr

Machining Designer

Boston-based Mechanical Engineer with 4+ years experience in mechanical design & CAD. - Advanced 3D modeling skills; able to produce parts, assemblies, and drawings in Onshape. - Expertise in design... Read more

Boston-based Mechanical Engineer with 4+ years experience in mechanical design & CAD. - Advanced 3D modeling skills; able to produce parts, assemblies, and drawings in Onshape. - Expertise in designing for 3D Printing and CNC machining. - Strong writing skills, able to create sketches, presentations, reports, and mechanical drawings. - Able to print and ship parts using in-house 3D Printers if needed for the project. - Experience in part sourcing as well as working with fabrication vendors. Available for free consultations and happy to answer any questions you may have!

$25/hr

$25/hr

Machining Designer

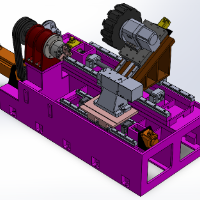

I am an innovative and detail-oriented Industrial Designer, CNC Programmer, and CAD/CAM Specialist with over 14 years of professional experience in product design, CNC machining, and 3D modeling. My e... Read more

I am an innovative and detail-oriented Industrial Designer, CNC Programmer, and CAD/CAM Specialist with over 14 years of professional experience in product design, CNC machining, and 3D modeling. My expertise lies in creating aesthetically pleasing, functional, and manufacturable designs across industries such as automotive, consumer products, manufacturing machinery, furniture, and electronics. CAD & 3D Modeling: Proficient in SolidWorks, Autodesk Inventor, Fusion 360, Alphacam, Biesse, and AutoCAD, with extensive experience in creating parametric models, assemblies, and technical drawings optimized for CNC machining and 3D printing. CNC Programming & Machining: Skilled in G-code programming, toolpath optimization, and CNC process setup, ensuring precision and efficiency in manufacturing. Product Design & Development: From concept to final prototype, I develop functional, ergonomic, and user-friendly products that meet ISO standards and client requirements. 3D Printing & Rapid Prototyping: Over 14 years of hands-on experience in designing and optimizing models for additive manufacturing with a focus on tolerance, strength, and material efficiency. PLC Programming & Machine Diagnosis: Capable of troubleshooting, electrical repairs, and integrating automation into manufacturing systems. Project Management & Client Collaboration: Proven ability to lead design teams, oversee quality assurance, and deliver cost-effective, innovative solutions tailored to each client’s needs. I combine creativity, technical precision, and problem-solving skills to transform ideas into high-quality, market-ready products. Whether it’s custom CNC parts, complex assemblies, or full product design, I ensure reliable results delivered on time.

$1/hr

$1/hr

Machining Designer

Hello Guys, I am Darshil Patel from India. I am currently working as a design engineer in Submersible Pump production company since 2021 I have a great experience about 3D Modelling, Machining Drawing... Read more

Hello Guys, I am Darshil Patel from India. I am currently working as a design engineer in Submersible Pump production company since 2021 I have a great experience about 3D Modelling, Machining Drawing, GD & T, Industrial Design.

$94/hr

$94/hr

Machining Designer

Growing up in an advanced mult-axis CNC machine shop and furthering my experience with studies in International Industrial Product Design Marketing and Mechanical Engineering I bring 25 years of theor... Read more

Growing up in an advanced mult-axis CNC machine shop and furthering my experience with studies in International Industrial Product Design Marketing and Mechanical Engineering I bring 25 years of theory and deep experience in the hands on / real world aspects of how precision industrial, medical, food processing, commercial, aerospace and consumer product products are conceptualized, prototyped and later produced and sourced. I have substantial experience in multi-axis CNC programming for high-speed, horizontal and vertical milling centers as well as multi-axis Swiss lathes (Citizen) via Mastercam. I am very well versed in a variety of materials and have years experience programming complex, multi-surfaced components to simple components, for short run prototypes, high speed, long run production and high-confidence lights out operations. In addition I have many years experience in CAD modeling and design via Solidworks 2018 including part, assembly and prints of which I also own one seat of latest 2018 version including Solid Works Simulation and the new, very impressive Solid Works Visualize. With Visualize I have the ability to not only design full solid models and assemblies but also create incredible, rendered real world pictures and images. I have designed, prototyped, sourced and brought to market several products from the ground up in various market segments including industrial, medical, food processing and aerospace. (including sheet metal, injection molded parts and of course precision machined parts with very tight tolerances). I currently own a Okuma MB-4000H Multi-Axis Horizontal Milling Center in which I can complete advanced protoypes to high speed, long run production runs. I am very confident that my education, real world experience and upbringing in a CNC environment has given me the ability to not only boldly design and or program components and products with disruptive, world class mechanical characteristics, it has given me the hands on experience to also design within the mindset of key variables like machine-ability and optimal material selection as this directly relates to final product cost. I have deep experience in optimization of solid model product design for machining and injection molding as well. I also hold several patents within the industrial and packaging spaces. I welcome any inquiry, as someone that truly enjoys this innovative space, I take projects with the assumption as if they were my own products. I embrace deep communication and work with the latest versions of all software I am versed in, with a deep emphasis on leveraging the amazing digital world we live in. I am willing to negotiate hourly rate based on the project.

$85/hr

$85/hr

Machining Designer

I’m a mechanical designer with 20+ years of CAD and product development experience, specializing in SolidWorks part and assembly design, reverse engineering, and 3D printing. My background spans manuf... Read more

I’m a mechanical designer with 20+ years of CAD and product development experience, specializing in SolidWorks part and assembly design, reverse engineering, and 3D printing. My background spans manufacturing, engineering, and IT, giving me a unique perspective on both design precision and practical execution. Highlights: Mechanical Design: Created 3D models, assemblies, and technical drawings for prototypes, production parts, and custom equipment. Reverse Engineering: Converted legacy parts and sketches into precise CAD models, often optimized for CNC machining, sheet metal, or 3D printing. Product Development: Delivered functional prototypes, BOMs, and DFM/DFA improvements to reduce cost and lead time. Manufacturing Support: Worked directly with vendors and production teams to ensure manufacturable, cost-effective solutions. Engineering Leadership: Managed cross-functional projects, balancing design, quality, and delivery in industries ranging from lab automation to firearms manufacturing. Specialties: SolidWorks 3D Modeling & Assemblies Reverse Engineering & Part Conversion 3D Printing & Prototyping Manufacturing Design (Sheet Metal, Machining, Plastics) Technical Drawings & GD&T BOMs, PDM, and Revision Control

$65/hr

$65/hr

Machining Designer

Design experience with plastics, sheet metal, rubber, welding, metal fabrication, Metal injection molding, machining, thermoforming, extrusions, advance surface design.

Design experience with plastics, sheet metal, rubber, welding, metal fabrication, Metal injection molding, machining, thermoforming, extrusions, advance surface design.

$81/hr

$81/hr

Machining Designer

*** What we do? *** 1/ Finite Element Analysis (FEA): - Predict product behavior through linear, nonlinear, thermal, and dynamic analyses - Estimate fatigue life and fracture propagation of produc... Read more

*** What we do? *** 1/ Finite Element Analysis (FEA): - Predict product behavior through linear, nonlinear, thermal, and dynamic analyses - Estimate fatigue life and fracture propagation of product - Analyse weld fatigue, vibration fatigue, low/high cycle fatigue, and composite fatigue - Optimise designs and validate product performance before production 2/ Computational Fluid Dynamics (CFD): - Inspect fluid flow, air flow, free surface flows (multiphase) - Analyse thermal management and heat transfer - Turbomachinery, turbulence and combustion - Fluid-Structure Interaction (FSI) and thermal FSI - Make faster and better decisions in the product development process 3/ Consulting Services: - Provide specialised solutions to engineering problems ranging from basic to complex analyses in the areas of structural analysis and fluid dynamics, applied mechanics and heat transfer. - Additional services include design verification/auditing, new product R&D, physics calculations. *** Why choose us? *** Our qualified services are the result of years of scientific study and international working experiences. The owner and experienced engineer, Tri Tien (Tri is pronounced as Tree), has more than 10 years in simulation and manufacturing industries, both in Australia and overseas. Before starting CAEbay, Tri had previously performed various roles as technical engineer, production & development engineer, and engineering head for many companies covering a range of industries including mechanical simulation, composite manufacturing, wood machining and fitness equipment manufacturing. Tri holds a Bachelor of Automotive and Engine Engineering from Ho Chi Minh City University of Technology, a Masters of Science from Konkuk University South Korea, and a PhD in Computational Engineering from University of Southern Queensland. Tri has published more than 15 peer-reviewed international journal articles and conference papers in the area of computational engineering. "CAE only delivers meaningful results if the engineer driving the computer fully understands the theory behind the simulation." *** What clients say? *** “It became clear that Tri has an unusual ability to computer model both physical objects and processes involving thermodynamics, movements of fluids and combinations of these.” Director Cliff Walker, Vacmobiles.com ltd., New Zealand. “We encountered some serious failure problems that halted our sales. Tri quickly identified the cause of the failures and invented a fail-safe substitution that allowed us to resume sales.” Thomas R. Anthony Ph.D, NAE., America. “With a very tenacious and robust problem solving ability, Tri was able to apply a deep technical knowledge into an array of projects to improve both existing systems along with the research into new areas of possible business.” David Pring, Managing Director, Timber and Laminate Services Pty Ltd., Australia.

$10/hr

$10/hr

Machining Designer

I am a dedicated 3D CAD designer with a solid foundation in Mechanical Engineering. Currently, I am pursuing my degree in Technology of Mechanical Engineering at Universitas Gadjah Mada, where I have... Read more

I am a dedicated 3D CAD designer with a solid foundation in Mechanical Engineering. Currently, I am pursuing my degree in Technology of Mechanical Engineering at Universitas Gadjah Mada, where I have developed expertise in 3D CAD modeling and parametric design. Throughout my studies, I have honed my skills in Onshape, SolidWorks, and AutoCAD, enabling me to create accurate, functional, and manufacturable designs for a variety of applications. My experience spans across designing mechanical components, product prototypes, and generating technical documentation, which has prepared me to deliver high-quality 3D models tailored to meet client specifications. During my internship at PT Adyawinsa Stamping Industries, I gained invaluable hands-on experience in CAD and CAE modeling, particularly focusing on automotive components and manufacturing processes. I was involved in designing components for the automotive industry, including 3D modeling, simulation, and process optimization. I also worked on creating detailed designs for production, ensuring that all parts met precise tolerances and were manufacturable. This internship gave me deep insight into the practical aspects of design and engineering, and I was able to leverage SolidWorks and Autodesk Inventor to optimize designs for manufacturing. In addition to practical experience, I have also obtained the Certified SolidWorks Associate (CSWA) certification, which demonstrates my proficiency in using SOLIDWORKS for creating 3D models, assemblies, and technical drawings. This certification allows me to confidently work on complex models, ensuring they meet industry standards for both design and manufacturing. My understanding of parametric modeling helps me to create flexible and easily adjustable designs, which is critical for meeting client requirements and ensuring manufacturability. My academic background includes coursework in various relevant subjects, such as CAD, CAE, Reverse Engineering, and Manufacturing Processes. These courses have provided me with a comprehensive understanding of design principles, as well as the ability to apply theoretical knowledge to real-world projects. In particular, Reverse Engineering has equipped me with the skills to analyze existing products and create accurate CAD models based on physical objects, which is essential for product development and prototyping. I have also achieved a 3.50 GPA (IPK), reflecting my commitment to excellence in both my academic and practical work. This strong academic foundation, combined with my internship experience and certification, has helped me develop a well-rounded skill set that I bring to every project I undertake. I am focused on delivering designs that not only meet functional specifications but are also optimized for the production process. I specialize in creating 3D CAD models for a variety of applications, including mechanical components, prototypes, and engineering assemblies. I ensure that all designs are created with a clear understanding of the required tolerances, material properties, and production methods. I work closely with clients to understand their specific needs and ensure that my designs align with their goals, whether for 3D printing, CNC machining, or other production methods. My design process involves creating parametric models, performing design validation, and generating technical drawings with precise dimensions and tolerances for manufacturing. Using Onshape's cloud-based platform, I can collaborate efficiently with clients, ensuring that the design process is transparent and that feedback can be quickly incorporated into the final product. This collaboration allows for real-time changes, reducing the risk of miscommunication and ensuring the design meets the client's expectations. I also provide multiple revisions to ensure the final design is aligned with the client's needs and goals. My services are particularly well-suited for students, professionals, and small businesses looking for high-quality 3D CAD design. Whether you need a mechanical part, product prototype, or engineering simulation, I am committed to delivering accurate, cost-effective, and manufacturable designs. My goal is to provide a seamless experience from the initial concept through to the final design, ensuring that the project is completed on time and within budget. With a strong foundation in both the theoretical and practical aspects of Mechanical Engineering and 3D CAD design, I am well-equipped to tackle a wide range of projects. My passion for design and problem-solving drives me to continuously improve my skills and stay up-to-date with the latest developments in the industry. I am excited to bring my expertise and dedication to every project I work on, helping clients achieve their design goals with precision and professionalism.I am a dedicated 3D CAD designer with a solid foundation in Mechanical Engineering. Currently, I am pursuing my degree in Technology of Mechanical

$38/hr

$38/hr

Machining Designer

More than 8 years of experience in SOLIDWORKS designing. From first idea to final product assistance. I WILL MAKE YOUR IDEA A REALITY !

More than 8 years of experience in SOLIDWORKS designing. From first idea to final product assistance. I WILL MAKE YOUR IDEA A REALITY !

$45/hr

$45/hr

Machining Designer

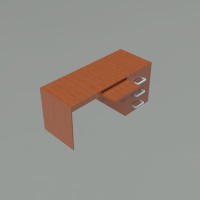

I am mechanical engineer have experience in manufacturing and designing more then 15 years. I can design 2D and 3D products as your requirements, production ideas, plastic mold design and modeling, re... Read more

I am mechanical engineer have experience in manufacturing and designing more then 15 years. I can design 2D and 3D products as your requirements, production ideas, plastic mold design and modeling, reverse engineering, research and development, prototyping and also help you to produce products from raw material to finish product. I have good knowledge in materials such as carbon steels, stainless steels and alloys. I also love to work on multi component assemblies and instruments. I use AUTOCAD, SOLIDWORKS, DELCAM software for designing, programming and manufacturing and KEYSHOT for rendering. Also have enough experience in operating CNC machining center, CNC turning center, Wire EDM and many more conventional machines. I did many projects on surgery instruments, Automotive parts and molds from design to manufacturing and production.

$25/hr

$25/hr

Machining Designer

Hi, I'm Mariano Garcia. I am a specialist in mechanical design with more than 10 years of experience designing special machines, jigs and fixtures, special parts and devices. I'm a CNC Programmer and... Read more

Hi, I'm Mariano Garcia. I am a specialist in mechanical design with more than 10 years of experience designing special machines, jigs and fixtures, special parts and devices. I'm a CNC Programmer and i offer profesional CAM solutions. Also I have a machining workshop with cnc machines. All to make your projects come true. I want to provide innovative solutions in mechanical engineering projects and generate long-term relationships with customers.

$13/hr

$13/hr

Machining Designer

I am Chetan Patel (B.Tech Mechanical Production Engineering). Completed my degree during the academic year 2005-06 from Marwadi College of Engineering affiliated under Saurastra University (INDIA). I... Read more

I am Chetan Patel (B.Tech Mechanical Production Engineering). Completed my degree during the academic year 2005-06 from Marwadi College of Engineering affiliated under Saurastra University (INDIA). I completed a master certificate course on computer aided tool engineering (MCTE) from Central Institute of Tool Design (CITD), Ahmedabad, India. siemens NX parametric was used for modeling the product.The Die was manufactured using conventional machining method and performed Plasting Injection Moulding to produce the final product.Polypropylene was used as the raw material for injection. 3) Modeled a project funded by Micro Small and Medium Enterprises (MSME) at CITD using Siemens NX. The project is in manufacturing stage and will be released in the market within few months. 4) I am working on my project to prevent Helmet theft. CAD models are prepared.

$25/hr

$25/hr

Machining Designer

Hello, I have my own company and for the past eight years I specialized myself in CAD/CAM software, CNC machines and robotics. I have experience with: - CAD/CAM software (ZW3D, ArtCam, Autodesk I... Read more

Hello, I have my own company and for the past eight years I specialized myself in CAD/CAM software, CNC machines and robotics. I have experience with: - CAD/CAM software (ZW3D, ArtCam, Autodesk Inventor, Solidworks, CimcoEdit) -Scanning software and reverse engineering ( ArtecStudio, Geomagic Design X, Geomagic Wrap) -CNC machining ( toolpaths with CAD/CAM programs, manual written in ISO G code) -Robotics - basic programming and milling programs for my production line - and I also have a KUKA training course for robots. -Eureka 5 ( Simulation and postprocessing software for 5 axis CNC machines and robots) A part of my portofolio (pictures only): https://www.dropbox.com/sh/l3drbxugt986ry1/AACxG84FJC19Rs3bSWynw2Yqa?dl=0 http://www.youtube.com/watch?v=hIiRL7gKy5I http://www.youtube.com/watch?v=9cmkF7DZAIU http://www.youtube.com/watch?v=HKA0iSPKqeQ More at: https://www.youtube.com/user/aalleexxblog More details I can give upon the request. Kind regards, Alex

$50/hr

$50/hr

Machining Designer

I have completed several design projects for toys and watches. My main skill lies in translating an idea from an initial concept, sketch or design and to come with a sound mechanical construction with... Read more

I have completed several design projects for toys and watches. My main skill lies in translating an idea from an initial concept, sketch or design and to come with a sound mechanical construction with a completed 3D assembly where all the component parts are manufacturable. Coming from a strong mechanical engineering, manufacturing background, I have many years of hands on experience, and have made many improvements for products already in manufacture. Proof of concept prototyping with 3D printing (FDM or SLA) or CNC machining is available to produce a functional prototype based on the 3D model assembly. This is necessary before going for a production run. I am close to the manufacturing bases in South China, and have a network of factories who can do small batch production runs. Summary of other activities: • Design & proof of concept prototypes of small mechanical devices and producing a set of 3D assembly models and 2D drawings to output to CNC, 3D printing and manufacture • Engineering drawings approvals new & for ongoing production to ensure finished product matches all specifications and requirements • Project management of existing production • Product audit for various consumer products (various consumer products) • Sourcing of various products & components • Sourcing of alternative supplier base for lower unit cost and improved quality with follow up factory audit • Factory QC and making necessary changes to production and future design and product development

$50/hr

$50/hr

Machining Designer

My name is Christian Ruiz. I am a highly analytical, performance-driven engineer with proven skill sets in 3D modeling, 2D technical drafting, and FEA analysis. For nearly 5 years I have been collabo... Read more

My name is Christian Ruiz. I am a highly analytical, performance-driven engineer with proven skill sets in 3D modeling, 2D technical drafting, and FEA analysis. For nearly 5 years I have been collaborating, developing and improving mechanical systems. I work in a variety of fields to analyze and evaluate large-scale, highly complex systems. I have repeated success in developing innovative designs with the intent to manufacture, while reducing costs. I will collaborate with you to improve and maintain your current systems, or to create new and innovative projects. I ensure that my designs are not only creative and unique, but also practical, usable and economically viable. In addition, I have a proven ability to manage multiple projects and meet critical deadlines efficiently. Degree: B.S in Mechanical Engineering from Santa Clara University Areas of Expertise: Software • Certified Solidworks Professional (CSWP) • Certified Solidworks Advanced Drawing Tools (CSWPA-DT) • Certified Solidworks Advanced Surfacing (CSWPA-SU) • Certified Solidworks Associate (CSWA) • Solidworks Simulation • Keyshot • Modflow Advisor • Adobe Photoshop and Premier Key Skills • Solid & Parametric Modeling • Geometric Dimensioning & Tolerancing (GD&T) • FEA Simulation • Stress and Strain Analysis • Mechanical Component Design • Design For Manufacturing (DFM) • Machining • Project Management and Quality Control • Test Plan Execution • Troubleshooting and Diagnostics • Superior Mathematics Aptitude • Electro-Mechanical Design

$4/hr

$4/hr

Machining Designer

Highly efficient, smart working and talented design engineer Concept development, new product design, manufacturing and construction methods Experienced in all design stages of a product Development... Read more

Highly efficient, smart working and talented design engineer Concept development, new product design, manufacturing and construction methods Experienced in all design stages of a product Development and manufacture including material selection, machining process

$1/hr

$1/hr

Machining Designer

I am a Mechanical Engineering major at Ohio State University, and I lead the Drivetrain team for the OSU Baja SAE team. I have completed design projects for Baja from initial design concept to manual... Read more

I am a Mechanical Engineering major at Ohio State University, and I lead the Drivetrain team for the OSU Baja SAE team. I have completed design projects for Baja from initial design concept to manual and CNC machining, so I understand design for manufacture principles I have also completed some small personal 3D printing projects.

$40/hr

$40/hr

Machining Designer

I am experienced in using CAD & CAM software to develop products from concept to manufacturing using 3D modeling and Machining skills.

I am experienced in using CAD & CAM software to develop products from concept to manufacturing using 3D modeling and Machining skills.

$10/hr

$10/hr

Machining Designer

A highly skilled machine designer with expertise in design of all types of machines, machine parts and assemblies. Expertise in selection of various machine parts such as motors, Pneumatic/Hydraulic C... Read more

A highly skilled machine designer with expertise in design of all types of machines, machine parts and assemblies. Expertise in selection of various machine parts such as motors, Pneumatic/Hydraulic Cylinders, ball screws, linear rails, chucks, bearings etc. I provide complete Design, Analysis and Detailing Services that include # Concept Generation and Preliminary Design # Selection of Machine Components such as Linear Guideways, Ball Screws, Servo Motors etc. # Layout Generation and Detailing # Creation of Ultimate Machine Body Structure using FEM Analysis # Assembly Modelling and Detailing # Part Modelling and Detailing # Creating Casting 3D Model for Machine Castings. # Creation of Fabrication, Weldment, Casting, Machining Drawing for Production. My services also include # 2D to 3D Modelling, Rendering # PDF to AutoCAD Drawing conversion, # Weldment, Casting and Machining Drawing with GD&T. # Assembly Modelling and Detailing, Exploded View, BOM Creation.

$13/hr

$13/hr

Machining Designer

I'm a motivated mechanical engineer . My Internship in CNC machining from Lovely Professional University has made me a proficient CNC programmer. I've explored mechanical device challenges in a capsto... Read more

I'm a motivated mechanical engineer . My Internship in CNC machining from Lovely Professional University has made me a proficient CNC programmer. I've explored mechanical device challenges in a capstone project about cryocooler's.I'm CATIA V5R20 ,Autocad 2D and 3D,certified from Internshala trainings, emphasizing my commitment to industry-standard tools.I'm eager to apply my skills in mechanical engineering and design . Let's connect and explore opportunities in these dynamic fields.

Machining Designer

Motivated Mechanical Engineer specializing in design, analysis, and optimization of mechanical systems. Experienced SolidWorks user with advanced skills in CAD modeling, simulation (FEA/CFD), and prot... Read more

Motivated Mechanical Engineer specializing in design, analysis, and optimization of mechanical systems. Experienced SolidWorks user with advanced skills in CAD modeling, simulation (FEA/CFD), and prototyping. Proven success in both traditional and additive manufacturing, including CNC machining and 3D printing. Passionate about delivering efficient and innovative solutions for engineering challenges.

$4/hr

$4/hr

Machining Designer

Mechanical engineer, with a strength in machine design, Working in one of the reputed company in production so has a good experience of fixture design, ergonomics and machining limitations. Can work w... Read more

Mechanical engineer, with a strength in machine design, Working in one of the reputed company in production so has a good experience of fixture design, ergonomics and machining limitations. Can work well with fixture designing, modelingetc

$15/hr

$15/hr

Machining Designer

As a Mechanical Engineer with 5 years of robust experience in new product development, I specialize in taking projects from initial design through to prototype and final production. My career has allo... Read more

As a Mechanical Engineer with 5 years of robust experience in new product development, I specialize in taking projects from initial design through to prototype and final production. My career has allowed me to work with pioneering companies in the renewable energy and sustainable technology sectors, including Livaah Innovations, Aktivolt Celtek Pvt Ltd, Emobi Manufactury Pvt Ltd, Thermodyne Systems, and Genesis Marine Technologies. At Livaah Innovations, I was instrumental in developing and promoting products aimed at renewable energy and sustainability, including power banks, chargers, UPS systems, and portable energy storage solutions. I continued to excel within the same group of companies, contributing to significant projects at Aktivolt Celtek and Emobi Manufactury. My notable projects included a 5kW inverter, advanced energy storage systems, motor controllers, EV chargers, and electric two-wheelers. My tenure at Thermodyne Systems focused on portable consumer electronics, where I further honed my skills in diverse manufacturing processes such as sheet metal fabrication, surface design, injection molding, die casting, and CNC machining. These experiences enriched my understanding and expertise in creating efficient, high-quality products. Currently, at Genesis Marine Technologies, I lead the engineering design of the world's first hybrid surf boat. This role has given me the opportunity to manage various projects, lead cross-functional teams, and ensure the timely delivery of innovative designs while maintaining cost efficiency. My leadership and project management skills have been key in driving projects from concept to completion. I am certified in Catia and Ansys by KKMSoft, which has equipped me with advanced capabilities in design and simulation. My proficiency in prototyping includes hands-on experience with 3D printing, vacuum casting, and other cutting-edge prototyping methods. Additionally, I have extensive experience in creating detailed product manuals, engaging packaging designs, instructional animations, product renderings, and graphic design. One of my strengths is my ability to work effectively across different time zones, facilitating smooth collaboration with global teams. I am passionate about being at the forefront of today's technological advancements and contributing to the development of future-forward products. My commitment to sustainability and renewable energy drives my dedication to delivering innovative engineering solutions that meet the highest standards of quality and efficiency.

$8/hr

$8/hr

Machining Designer

A highly motivated Mechanical Engineer with over 10 years of practical on-site experience in power generation industry (mapnablade co ) and 5 years in electromotor industry, specializing in: • Toolin... Read more

A highly motivated Mechanical Engineer with over 10 years of practical on-site experience in power generation industry (mapnablade co ) and 5 years in electromotor industry, specializing in: • Tooling design (Rotor & stator Die Stamping & fixture) • Process development and improvement, • CNC ( wirecut Charmilles Robofil 290 & Ultracut S2) Programming And Operating Milling &Turning Programming & operating -CAD CAM with Nx & Mastercam - simense 840 D Trained in Spinner Company in Munchen Germany. • Quality control • 3D modeling and preparing technical Document • FMEA (Failure Mode and effect Analysis) - Heat treatment, - Material selection, - Process Planning - Process Manufacturing. - selecting Tools (insert,holder,solid tools,) Trained in seco & Sandvik & YG1 tools seminar. - GD & T -SAP -Gear Design and production Able to work as a team member or independently as well as being a team leader , fast learner, analytical and innovative.Machining Fixture Design for new Gas Turbine blades (V94.2-GT13E2-Zoria Blade & Vane-MAP2B- GE-F6 & F9 )-.

$25/hr

$25/hr

Machining Designer

I’m a mechanical engineering professional with practical experience in machine manufacturing, product design, and CNC programming . Proficient in CAD/CAM tools like TopSolid and SolidWorks, I’ve worke... Read more

I’m a mechanical engineering professional with practical experience in machine manufacturing, product design, and CNC programming . Proficient in CAD/CAM tools like TopSolid and SolidWorks, I’ve worked on the design and development of industrial screws, barrels, and custom extrusion machinery. At Hi Tech Screw Barrel Works and Helix Extrusion Technology Pvt. Ltd., I was deeply involved in the complete manufacturing cycle—handling design, programming, and machining using advanced equipment. I also gained hands-on experience with tread milling, lathe, grinding, polishing, and manufacturing of high-precision extrusion machines for the plastic industry. My core strengths include technical drawing, CNC operation, and delivering practical, efficient mechanical solutions. I’m committed to quality work and continuous improvement in every project I take on.

$6/hr

$6/hr

Machining Designer

Computer Aided Engineering (CAE) Service Provider Works on CAD, FEA, CFD, MBD, machining & more. Constantly exploring all mechanical engineering tools. Vast industrial experience serving industries li... Read more

Computer Aided Engineering (CAE) Service Provider Works on CAD, FEA, CFD, MBD, machining & more. Constantly exploring all mechanical engineering tools. Vast industrial experience serving industries like Coal India, Aduza automation, Schlumberger(SLB), Dg Takano Japan, IISc Banglore, IIT Dhanbad and National Taiwan University etc. Message for any collaboration✨

$15/hr

$15/hr

Machining Designer

▪ Responsible for the execution of 3D CAD Design projects in industrial automation and metalwork ▪ Execution, inquiring and purchasing of technical drawings in 2D CAD for the production of mechanical... Read more

▪ Responsible for the execution of 3D CAD Design projects in industrial automation and metalwork ▪ Execution, inquiring and purchasing of technical drawings in 2D CAD for the production of mechanical components ▪ Preparer in CAM for component machining in CNC ▪ Sizing, inquiring and purchasing equipment for integration ▪ Responsible for the construction and Assembly of industrial equipment and structures ▪ Management and planning of projects ▪ Surveys, budgeting and project billing according to the customer's needs

$1/hr

$1/hr

Machining Designer

Last updated: Nov 13, 2025

Machining refers to the process of turning a piece of raw material into the desired shape, size, and dimensions by cutting and removing excess material away. It’s an integral part of the production process; in fact, it’s safe to say that it’s one of the backbones of the manufacturing industry. Without machining, it would be incredibly difficult to produce high-quality products, from simple ones like plastic home decorations to complicated objects like aircraft components.

Historically, machining was done by hand, but this changed over the years as technology became more and more advanced and modern manufacturing procedures and equipment were developed. Today, most machining processes are done through computer numerical control (CNC) machines, which store programmed commands in their storage medium and use these commands to automatically control tools and equipment. CNC machines produce highly precise products in a fast and efficient way, allowing companies to manufacture high-quality goods in large volumes while keeping production costs down.

But, while CNC machines have the ability to control tools in a precise and accurate way, the digital instructions on how to do this are not pre-built into them. This means that it’s up to the manufacturers to enter the commands into the machines and give them instructions on how to cut and drill into materials.

This is where machining freelancers from Cad Crowd come in. With their expertise in computer-aided design (CAD) software as well as computer-aided manufacturing (CAM) programs, they can create digital commands for CNC machines to follow. Once these instructions are loaded into the machines, they will know how to process the materials and create a product that matches the 3D CAD design.

So, if you’re in the manufacturing business, get the help of our freelance machining experts now. They can assist you in every step of the way, from creating concept sketches and detail drawings of your products to making 3D CAD drawings that are keyed with the commands for CNC machines to follow. Simply tell them what your ideas and requirements are, and they’ll deliver excellent results on time and within your budget.

One way to choose the right freelancer from Cad Crowd is to hold a contest. Seek out designers whom you think are the right fit for your project, and ask them to submit a design for your product along with the appropriate program for CNC machines. Review the entries you receive, then pick the design that best suits your needs and preferences.

If you have a large project or need ongoing help, you’ll want to use our hourly machining services. If you opt for this, we’ll select a vetted designer on your behalf, and you can communicate with him through email or phone as he tackles the task over a few days or weeks. You’ll only pay for the specific amount of time that the freelancer works on your project (up to the last second), which can result in substantial savings. Since you’ll work with a single freelancer on an ongoing basis, you can rely on someone who already knows what you want, and you’ll avoid wasting time and energy on training new designers every now and then.

Whichever method you choose, you won’t go wrong with hiring machining freelancers from Cad Crowd. Open your design contest now, or contact us to learn more about our services.