$63/hr

$63/hr

Manufacturing Processes Designer

My Outlook: Every product design project begins with a jumble of vague puzzle pieces. The pieces… market analysis, competitive analysis, price points, innovation, differentiation, aesthetics, concinn... Read more

My Outlook: Every product design project begins with a jumble of vague puzzle pieces. The pieces… market analysis, competitive analysis, price points, innovation, differentiation, aesthetics, concinnity, function, ergonomics, materials, manufacturing processes, tooling, assembly, packaging, shipping, users, manufacturers, costs, and the client. A myriad of considerations assemble into a design that makes your product unique, pertinent, targeted within its market, and profitable… a tangible object of desire and promise... a crisp image that makes sense. Every product wants to be something… to be desired and to realize its potential. I strive to stimulate that desire and optimize that potential… to solve the puzzle. My clients' success ensures my own and realizing that desire and potential benefits us both. My Experience: I use my degree in industrial design as a product designer/developer covering a wide variety of products. I have 20+ years of 3D modeling and product development experience. I have the resources to do it all... from concept to point of purchase and everything in-between. My Feedback, received and given: “Steve did great work helping us detail our product for manufacturing. He took the time to really understand the project and its intricacies instead of diving head first and by the end of this job, had an intimate understanding of all the details. He is talented and was willing to research new methods to help meet our stringent product constraints. We went through several discussions and he was excellent at being responsive and keeping things on track. He produced high quality solidworks assemblies and files. Overall he went above and beyond what was expected of him. Highly recommended contractor, A+++” —robocular “Antoine is an outstanding client to work with. He's quite knowledgeable and organized with clearly established goals coupled with exceptional communication skills. This project had some challenging constraints outside typical manufacturing and product design and development norms, but we worked through these challenges while staying within the target budget for the product. This project was more than I had bargained for, but I relished the challenge and Antoine appreciated the effort I put into it, which made this job particularly satisfying. I hope to work with Robocular again in the future.” —Io-Design “Working with Steve was a pleasure, not only do I think he’s an all-around good guy, but his approach to our project was great. He was able to take our idea and bring all his experience in making it better. Our initial idea was transformed into a product that ended up being cheaper to produce and nicer, while being more practical. We were able to overcome the hurdle we encounter and find solution that made it work! Also, he often came back with a different idea of doing things that were very practical. I Highly recommend him. ” — yvesl “Yvesi came to me with the need for a design for a grain dispenser for feeding livestock. As is often the case, he showed me a design from another designer he had hired that didn't meet the product requirements. This design was too large and could not be sold at a profit due to inappropriate and impractical manufacturing processes. Through close collaboration, we came up with a design that is half the size, more aesthetically pleasing and user friendly, and is simple to assemble and install. Also, it will be sold at a projected price point that is 10% lower than the competition at a projected 90% profit margin while enjoying relatively low capital expenditures. It was a pleasure working with yvesi on this project and I'm looking forward to working with him again in the future.” —Io-Design “Io-Design was extremely professional, knowledgeable, and easy to work with. He provided designs that were exactly what we were looking for and he took into account the manufacturing. I would recommend him to anyone. ” — Westone “As mentioned in the job description, Blake works for a company that represents the ultimate, uncompromising audio experience – revolutionary sound; unrivaled comfort and fit; with superior, innovative design in the earphone market. While they are well known among audiophiles and professionals who rely on uncompromising audio, they are less so in the consumer market. This project was part of an effort to update their earphones look, feel, and user experience to the level of their best in class earphone technology... the challenge being that their existing monitors/earbuds were to remain unchanged. Through close collaboration, we came up with a design that practices concinnity with the existing monitors, introduces innovative solutions, targets the consumer market, and enhances brand recognition. Superior design was the point of this project and together we have achieved that goal. Blake is a pleasure to work with and I'm looking forward to the next project.” —Io-Design

$10/hr

$10/hr

Manufacturing Processes Designer

Mechanical Design Engineer with over 6 years of experience, I specialize in developing and designing mechanical parts with precision and innovation. My expertise spans a wide range of skills including... Read more

Mechanical Design Engineer with over 6 years of experience, I specialize in developing and designing mechanical parts with precision and innovation. My expertise spans a wide range of skills including: 3D Modeling: Creating detailed and accurate 3D models. 2D Detail Drawing: Drafting comprehensive technical drawings. Manufacturing Drawings: Generating drawings optimized for production. Photorealistic Renderings: Utilizing Keyshot for lifelike visualizations. 3D Printing Design: Designing for additive manufacturing processes. Industrial Product Design: Developing products with a focus on functionality and aesthetics. PCB Enclosures: Designing enclosures tailored for electronic components. Metalwork and Fabrication Drawing: Expertise in metal fabrication techniques. Reverse Engineering: Analyzing and recreating existing designs. Optimizing Manufacturing Processes: Improving efficiency and cost-effectiveness. I leverage cutting-edge tools including Solidworks, AutoCAD, Fusion 360, and Geomagic Design X to deliver designs that are not only innovative but also optimized for manufacturability and efficiency. My goal is to collaborate closely with clients to transform concepts into tangible, successful products. Let's collaborate to bring your ideas to life and create something exceptional!

$1/hr

$1/hr

Manufacturing Processes Designer

CATIA V5: Modeling in all modules Solid, Sheet-Metal, Surface (Plastics) and Assembly. GD&T as per ASME Y 14.5 (1994/2009/2018). Documentation as per ISO 5457.(Drafting). Customized BOM creation. Know... Read more

CATIA V5: Modeling in all modules Solid, Sheet-Metal, Surface (Plastics) and Assembly. GD&T as per ASME Y 14.5 (1994/2009/2018). Documentation as per ISO 5457.(Drafting). Customized BOM creation. Knowledge in various manufacturing processes. Familiar with Conventional Machining processes. Knowledge in various material types and properties.

$40/hr

$40/hr

Manufacturing Processes Designer

I am a professional SolidWorks designer with over 5 years of experience specializing in machine design and mold design. I have worked extensively on industrial machinery, injection molds, and product... Read more

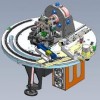

I am a professional SolidWorks designer with over 5 years of experience specializing in machine design and mold design. I have worked extensively on industrial machinery, injection molds, and product design, ensuring precision, functionality, and manufacturability. My expertise includes creating complex 3D models, technical drawings, and optimizing designs for cost-effective manufacturing processes. Key Highlights of My Experience: 1. Designed CNC machine components, enhancing performance and reducing material usage. 2. Created custom industrial machinery designs tailored to client specifications. 3. Developed detailed assembly drawings and exploded views for large-scale machine systems. 4. Specialized in mechanical parts design with high precision for automation equipment. 5. Experienced in design optimization to ensure compliance with GD&T (Geometric Dimensioning & Tolerancing) standards. 7. Collaborated with manufacturing teams to streamline prototyping and production phases. 8. Delivered designs for heavy-duty machines, including hydraulic systems and gear assemblies. I take pride in offering innovative solutions to meet the challenges of modern manufacturing. Let’s collaborate to turn your ideas into reality.

$12/hr

$12/hr

Manufacturing Processes Designer

Detail-oriented and highly skilled CAD Designer specializing in SOLIDWORKS Sheet Metal and Welding Industry applications. Demonstrates extensive expertise in designing, modeling, and detailing sheet m... Read more

Detail-oriented and highly skilled CAD Designer specializing in SOLIDWORKS Sheet Metal and Welding Industry applications. Demonstrates extensive expertise in designing, modeling, and detailing sheet metal components and assemblies to meet industry standards and client specifications. Proficient in developing innovative welding solutions, optimizing manufacturing processes, and ensuring seamless integration between sheet metal fabrication and welding operations. Adept at creating precise technical drawings, performing design validation, and collaborating with cross-functional teams to deliver high-quality, cost-effective CAD solutions. Committed to continuous learning and applying best practices to enhance productivity and design accuracy within the sheet metal and welding industry. SOLIDWORKS CAD Designer specializing in the design and development of Air Handling Units (AHUs) and HVAC systems. Possessing extensive experience in creating precise 3D models, detailed drawings, and assembly documentation in compliance with industry standards. Adept at collaborating with engineering teams to optimize design performance, enhance functionality, and ensure manufacturability. Strong understanding of HVAC components, airflow dynamics, and regulatory requirements, combined with excellent problem-solving skills and a commitment to delivering high-quality CAD solutions. Proven ability to manage multiple projects efficiently while maintaining accuracy and attention to detail.

$5/hr

$5/hr

Manufacturing Processes Designer

Welcome to my profile! I'm a seasoned SolidWorks 2D/3D Designer and machine specialist with a passion for crafting innovative solutions. With a wealth of experience in designing and manufacturing dive... Read more

Welcome to my profile! I'm a seasoned SolidWorks 2D/3D Designer and machine specialist with a passion for crafting innovative solutions. With a wealth of experience in designing and manufacturing diverse machines, modifications, and automation solutions, I bring a comprehensive skill set to the table. My expertise extends across a spectrum of disciplines, including PLC programming, pneumatics, sensors & actuators, as well as motor drives and controls. I thrive on integrating these technologies seamlessly into my designs to create efficient and reliable systems. In addition to my prowess in design, I boast hands-on experience in manufacturing and machining technology. From CNC machining to laser and plasma cutting, I'm well-versed in utilizing advanced techniques to bring concepts to life with precision and speed. My strengths lie in my ability to conceptualize innovative solutions tailored to specific needs, ensuring optimal functionality and performance. I take pride in my track record of delivering projects on time and within budget while exceeding client expectations. With a solid educational background complementing my practical experience, including Bachelor of Technology in Mechatronics Engineering, I am equipped to tackle complex challenges head-on and deliver results that speak for themselves. Whether you're seeking to optimize your manufacturing processes, develop cutting-edge automation solutions, or bring your ideas to life with precision engineering, I'm here to turn your vision into reality. Let's collaborate and transform possibilities into tangible achievements.

$31/hr

$31/hr

Manufacturing Processes Designer

Bachelor in Mechatronics Engineering with experience in software management Windows and Linux, manufacturing processes, SAP logistics, electronics, data science for Python and CAD design. Studies abro... Read more

Bachelor in Mechatronics Engineering with experience in software management Windows and Linux, manufacturing processes, SAP logistics, electronics, data science for Python and CAD design. Studies abroad, focused on automotive design. Experience in the area of logistics and customs administration, focused on transport services for projects in the energy industry, such as oil and natural gas for the production of electrical energy. SAP consultant with experience in the automotive industry, especially the brands of the Volkswagen group with the SAP UNIT platform. Qualified SAP specialist with experience in SAP Logistics. Qualified CAD drawing professional with practical experience in the use of design techniques and the production of plans, prototypes, sketches and precision technical models.

$25/hr

$25/hr

Manufacturing Processes Designer

I am a Mechanical Engineer with 7 years experience in the Aerospace , and 5 years in the Automotive industries. Many years of 3D CAD work; excellent in CATIA, SolidWorks, and AutoCad. Expert in Finite... Read more

I am a Mechanical Engineer with 7 years experience in the Aerospace , and 5 years in the Automotive industries. Many years of 3D CAD work; excellent in CATIA, SolidWorks, and AutoCad. Expert in Finite Element Modeling (CATIA, ABAQUS, LS-DYNA) for both composite and homogeneous materials. Hands on experience with manufacturing processes for Aluminum, Composites, and metal bonded products.

$20/hr

$20/hr

Manufacturing Processes Designer

I am a mechanical engineer and production manager with expertise in product design, prototyping, and manufacturing processes. I specialize in creating efficient production methodologies and overseeing... Read more

I am a mechanical engineer and production manager with expertise in product design, prototyping, and manufacturing processes. I specialize in creating efficient production methodologies and overseeing every stage of the manufacturing process, from concept to delivery. With proficiency in SolidWorks, I provide 3D modeling, detailed technical drawings, and simulation services for both metal and wood structures, machinery, and furniture design. My goal is to deliver high-quality designs optimized for production and functionality. Whether you need custom product designs, realistic 3D visualizations, or manufacturing-ready CAD models, I am here to help. Let's bring your ideas to life! Services I Offer: 1. 3D Modeling & Product Design 2.Technical Drawings & Blueprints 3.CAD Prototyping & Simulation 4. Manufacturing Optimization 5.Sheet Metal & Furniture Design Let's discuss your project—message me today!

$0/hr

$0/hr

Manufacturing Processes Designer

I am a versatile SolidWorks Specialist with expertise in creating accurate 2D and 3D models. I excel in motion analysis, optimizing designs for functionality, and integrating CAM techniques for stream... Read more

I am a versatile SolidWorks Specialist with expertise in creating accurate 2D and 3D models. I excel in motion analysis, optimizing designs for functionality, and integrating CAM techniques for streamlined manufacturing workflows. My accomplishments include successful motion analysis, efficient manufacturing processes, and optimized design solutions. As a 4th-year Mechanical Engineering student, I have actively engaged in a diverse range of projects, showcasing my skills and dedication. One notable project I participated in was ASME Project , where I led a team in designing and prototyping an energy-efficient mechanism, resulting in a significant reduction in energy consumption. Additionally, I successfully completed a project focused on 3D printing, where I contributed to the development of a functional 3D printer. These experiences, combined with my ongoing education in Mechanical Engineering, have equipped me with a strong foundation and a passion for innovation in the field.

$30/hr

$30/hr

Manufacturing Processes Designer

I'm a professional 3D jewelry designer with a background in traditional bench work. I specialize in high-precision CAD modeling using Matrix and Rhino, delivering casting-ready designs, clean STL file... Read more

I'm a professional 3D jewelry designer with a background in traditional bench work. I specialize in high-precision CAD modeling using Matrix and Rhino, delivering casting-ready designs, clean STL files, and photorealistic renders. My experience includes engagement rings, bracelets, earrings, and minimalist collections — both custom-made and for mass production. With a solid understanding of manufacturing processes, I ensure every file is optimized for real-world results. Let’s turn your jewelry ideas into reality — from sketch to casting.

$15/hr

$15/hr

Manufacturing Processes Designer

As a Mechanical Engineer with a CSWP certification and expertise in Geometric Dimensioning and Tolerancing (GD&T), I bring a wealth of knowledge in both theoretical principles and practical applicatio... Read more

As a Mechanical Engineer with a CSWP certification and expertise in Geometric Dimensioning and Tolerancing (GD&T), I bring a wealth of knowledge in both theoretical principles and practical applications. Proficient in SolidWorks and AutoCAD, I specialize in leveraging these tools to design innovative solutions and optimize manufacturing processes. My expertise extends beyond traditional engineering boundaries to encompass designing services tailored to meet diverse needs. Whether it's conceptualizing product designs, creating detailed engineering drawings, or optimizing mechanical systems for efficiency and performance, I am dedicated to delivering high-quality solutions that exceed expectations. In essence, I combine technical proficiency with a passion for design to provide comprehensive engineering and design services that drive success in various industries.

$19/hr

$19/hr

Manufacturing Processes Designer

Having 11+ years of experience in the Field of Mechanical Design Engineer. Ability to create 3D Model, Concept Design and Complete Drafting Design for Manufacturing. Able to produce a complete D... Read more

Having 11+ years of experience in the Field of Mechanical Design Engineer. Ability to create 3D Model, Concept Design and Complete Drafting Design for Manufacturing. Able to produce a complete Design to Manufacturing solutions with all the process parameters for efficient manufacturing methods.

$63/hr

$63/hr

Manufacturing Processes Designer

I am a mechanical engineer and have worked in some sort of design or manufacturing setting for almost 10 years. I specialize in helping companies do three things: 1. Making your product more cost-... Read more

I am a mechanical engineer and have worked in some sort of design or manufacturing setting for almost 10 years. I specialize in helping companies do three things: 1. Making your product more cost-efficient to produce 2. Refining your product so that it is easy for the customer to use 3. Accelerating your development process. I know speed is key when getting any new project started so I get you what you need ASAP. Some of my accomplishments so far -Helped a company that raised 500k in crowdfunding to develop the product they are now selling, reducing their manufacturing cost by over 20% -Helped a company raise their first round of funding by designing and prototyping their first product -Worked with product development firms with large customers to work out kinks in their designs and fabricate their prototypes -Worked with another crowdfunding campaign to make develop their beta-testing product. -Designed tooling for robotic arms to automate manufacturing processes resulting in massive reduction in labor cost I am proficient in the following disciplines -SolidWorks 2018 -Inventor 2018 -FEA (Finite Element Analysis - finding the weak points in a structural design) -Rapid prototyping (3D Printing, CNC Machining, etc.) -Design for manufacturing I work with a small 3D Printing company here in Chicago that can produce very high quality 3D prints with an excellent turnaround time. I also have a complete workshop with saws/mills/drills/CNC where I can build pieces or prototypes for virtually any project. I love working with startups to get their product moving. I like the fast pace environment and love seeing something we work on go to market.

Manufacturing Processes Designer

I've worked in Research & Development as both a CAD Draftsman and Engineering Technician. I have experience in manufacturing processes and rapid prototyping.

I've worked in Research & Development as both a CAD Draftsman and Engineering Technician. I have experience in manufacturing processes and rapid prototyping.

$23/hr

$23/hr

Manufacturing Processes Designer

TRANSFORMATION OF IDEAS INTO WORKING DRAWING & CONCEPTS. - That's what I do A passionate SOLIDWORKS professional with more than 3 years of experience in Engineering design and drafting field. I am... Read more

TRANSFORMATION OF IDEAS INTO WORKING DRAWING & CONCEPTS. - That's what I do A passionate SOLIDWORKS professional with more than 3 years of experience in Engineering design and drafting field. I am currently working as Manufacturing Engineer in leading Manufacturing Company in Ontario, Canada. Aviation Engineering (Mechanical) and Automated Manufacturing under my academics qualification, provides me with skills and knowledge of Designing & Manufacturing field. My capabilities include working from simple object designing to Factory layout in CAD. If you need help with Jig & Fixture design, Prototyping, Mechanical design & drafting and workplace design, HIRE ME. I would love to have a coffee with you and discuss innovative solutions for your project.

$16/hr

$16/hr

Manufacturing Processes Designer

Committed to provide quality service with honesty, I am a Mechanical Engineer having 17 years experience in Product / Tool, Machine Design, Furniture Design, Concept Development, Product Development.... Read more

Committed to provide quality service with honesty, I am a Mechanical Engineer having 17 years experience in Product / Tool, Machine Design, Furniture Design, Concept Development, Product Development. Being an expertise in Solid-works, Solid-edge, Uni-graphics, Sketch-up & Auto-cad, I mostly test everything in 3D before making detail drawings, most of the time. I am very well versed with manufacturing processes & thus provide designs/drawings ready for manufacturers with all the required files including stl/step/iges/dxf/dwg/pdf/rendered images etc. Being a full time designer, I can provide quick turnaround, so you can rely on me for deadline results. I have completed more than 12 years of working via Odesk/▒▒▒▒▒▒ & have worked with more than 200 clients.I have delivered desired results for every project & believe in accepting only those projects for which I can provide desired results. I have worked on machines/machine components, sheet metal products, wooden/steel/sheet metal furniture items, Enclosure/casing for electronic devices, Plastic injection molded products, manufacturing drawings, consumer accessories, wearable products & many more. Product Design/Prototype for 3d printing. Looking for long term association with the employers and provide the best services. Services offered : 1. 3D-Modeling / conversion / house plans /Interior Design. 2. Concept to product development. 3. Product / Tool / Machine design. 4. Manufacturing drawings. 5. General fabrications. 6. Sheet metal developments/Injection molded parts/ products for pressure die casting. 7. Component & Assembly drawings. 8. Component costing. 9. Rendering. 10.Technical Solutions. 11. Prototypes / 3D printing. 12. Reverse Engineering. Thanks & Regards, Shiv K Mittal

$80/hr

$80/hr

Manufacturing Processes Designer

As an experienced engineer with expertise in design and optimization, my strength lies in my ability to think out of the box and get the context right. I believe in caring for design intent and unders... Read more

As an experienced engineer with expertise in design and optimization, my strength lies in my ability to think out of the box and get the context right. I believe in caring for design intent and understanding the subtleties that can be useful for enhancing understanding. One of my notable projects involved designing and optimizing a connecting rod. In this project, I utilized my creativity and innovative thinking to come up with novel design solutions for improving the performance of the connecting rod. I analyzed the existing designs and identified areas where optimization could be done to enhance the overall efficiency and durability of the component. Through my meticulous research and analysis, I was able to identify key parameters such as material selection, geometric design, and manufacturing processes that could impact the performance of the connecting rod. I thoroughly analyzed the trade-offs and made informed decisions to arrive at the optimal design solution. I also paid great attention to design intent, ensuring that the final design met the functional requirements while also considering factors such as cost-effectiveness, manufacturability, and environmental impact. I leveraged my understanding of subtleties in the design process to come up with innovative solutions that improved the overall performance of the connecting rod. The result of my project was a highly optimized connecting rod design that demonstrated improved performance, durability, and cost-effectiveness compared to the previous designs. The success of this project highlighted my strengths in thinking out of the box, getting the context right, caring for design intent, and understanding the subtleties that can enhance the overall understanding and effectiveness of a project.

$30/hr

$30/hr

Manufacturing Processes Designer

Hello, I’m Anthony, a Mechanical Engineer from Colorado School Of Mines. I have over ten years of combined experience on Solidworks and Inventor. That includes other partner softwares such as masterca... Read more

Hello, I’m Anthony, a Mechanical Engineer from Colorado School Of Mines. I have over ten years of combined experience on Solidworks and Inventor. That includes other partner softwares such as mastercam and fusion 360. I am an engineer experienced in CNC milling, 3D printing, casting, forging, sheet forming, welding, and many other manufacturing processes. I’m also experienced in FEA, flow simulations, supply chain management, and overall design. My best talents are simulating and iterating parts for maximum efficiency. This can be used to maximize strength, weight, air flow, temperature, or any other performance criteria. I’m also a “Helluva” engineer and can provide responsibly priced consulting. However, I can also tackle “simple” parts quickly and cost effectively. I work for the state and have easy work hours. I would like to use my skills and knowledge to help others and make some side money. This allows me to give the proper time with each project I accept to accurately capture my clients goals. Thank you for your time to consider me and I look forward to helping you reach your goals.

$15/hr

$15/hr

Manufacturing Processes Designer

Progress. Perfection. Practicality. Like any industrial designer and design engineer, I love to change the world around me for the better, to rethink familiar things, their structure and functions... Read more

Progress. Perfection. Practicality. Like any industrial designer and design engineer, I love to change the world around me for the better, to rethink familiar things, their structure and functions for the sake of constant improvement. Creating new things is an absolute necessity for all humanity and I want to be part of this progress. I will do this no matter what, this is my calling, I want to see this world in its best version. Even if I can’t work, if someone decides to create hell in the place where I live and everyone around me, I will just continue on my way and move to another place. If there are no companies that want to cooperate, I will do it for myself. If I don’t have the tools at hand, I’ll try to make my own. I haven't built an airplane or a satellite yet, but I still have a lot of time ahead of me. I constantly develop my skills and explore new areas regarding my work and ideas without hesitation. So, within six months, I mastered industrial welding robots, their design, operation, maintenance, and also developed several large structures for them (for example, a linear track (7th axis) and various welding movable jigs). I was a little into bicycles, but didn't think much about how they were designed. I was not afraid to take on the project of designing a specific bicycle. During the work, I collected a huge amount of data about materials, their manufacturing processes, components that would be suitable for this project, found documentation for each of them so that everything would fit exactly, developed a design and tested all possible loads on the structure in simulations. Need to make an unusual ultimate rig for sim racing? Great, I will be happy to master this entire area in order to develop the most interesting design, as well as try out many designs to choose the best one. What does the future hold for additive technologies? I’m also interested, because I have a whole concept for an additive factory, which, it seems to me, can replace classical factories. I will be happy to work together towards a better, more beautiful and comfortable world!

$35/hr

$35/hr

Manufacturing Processes Designer

I am a mechanical design engineer who is currently involved in innovative product development providing support on hardware and mechanical aspects. I have extensive manufacturing experience in metalw... Read more

I am a mechanical design engineer who is currently involved in innovative product development providing support on hardware and mechanical aspects. I have extensive manufacturing experience in metalworking manufacturing industry. Additionally I am have also woodworking, 3D printing, injection molding and laser cladding manufacturing processes. I am an expert Solidworks, Autodesk inventor, Rhino and Google Sketchup user. In addition I have some experience in using Catia v5. I am also proficient in performing finite element method analysis for structural as well as thermomechanical steady-state and transient analysis in various FEM software packages such as Ansys and Comsol multiphysics . My professional day-to-day activity involves working with the following manufacturing processes: sheet metal/weldment profile material CNC laser cutting, CNC bending, rolling, CNC-milling, CNC-turning, welding, assembly, outsourcing, wiring and PCB board design. I can provide support both on product development as well as manufacturing aspects of your porjects.

$35/hr

$35/hr

Manufacturing Processes Designer

I'm capable in mechanical engineering design, consideration, and calculation. Combination of my knowledge of engineering and design as well as knowledge of materials science and manufacturing processe... Read more

I'm capable in mechanical engineering design, consideration, and calculation. Combination of my knowledge of engineering and design as well as knowledge of materials science and manufacturing processes is very useful to create functional & marketable consumer products, mechanical parts, and machines. Furthermore, my skill in using CAD, CAM, & CAE software like Solidworks, Mastercam, AutoCAD, & Inventor is also supporting & accelerating me to present 3D models and technical drawings of those designs. I have a lot of experiences in the jobs from design process to fabrication of those products. I had completely finished many projects of design and fabrication of various custom-made machine. Dough lifter machine for Dunkin Donuts in 2011. Chain conveyor, tumbler, & lifter for paving stone manufacturer in 2012. Tabletop chain conveyor, modular belt conveyor, & pusher for isotonic beverage in 2013. Washer conveyor, screw conveyor, and mixing tank for food industry in 2014. And there are many other more I can't mention them all. In 2021, I created 3D designs of mineral water bottle blow molding from 3D modeling of all mold parts to 3D assembly parts using Solidworks. I also make CNC programming of the machining process using Mastercam and supervise the fabrication process to be finished mold as the specifications. I had also made 3D models of Radio-Controlled (RC) Cars of CJ7 Jeep and Toyota Hardtop Jeep in 2020 & 2021 using Solidworks. Actually, I had produced a lot of 3D models and 2D technical drawings of various parts and products that I can’t present them all in my portfolios. Besides that, nowadays I actively be an Instructor in my Training Institution to teach: 1. Solidworks for Solid modeling, Surface modeling, Mold tools, Plastics, Sheet Metal, Simulation, & Weldment 2. Mastercam for programming CNC machines of 3Axis Mill & Lathe. 3. Autocad 2D & 3D for technical drawing. 4. Inventor for Solid modeling, Accelerator, Weldment, Analysis.

$20/hr

$20/hr

Manufacturing Processes Designer

Hello, I am an Industrial Design Engineer with 5 years of experience in the field of product development working in multicultural teams from India, Estonia, China and Saudi Arabia. I have been involv... Read more

Hello, I am an Industrial Design Engineer with 5 years of experience in the field of product development working in multicultural teams from India, Estonia, China and Saudi Arabia. I have been involved in projects requiring the development of innovative mechanical systems along with the Industrial design of the product. I have successfully designed and developed mechanical systems for padlocks, jimmy-proof lock, electronic pruners. I have also been involved in the development of Industrial design for cookware, coffee tumblers, kick scooters,s and various other consumer products. At present, I am heading the design and mechanical development of a kitchen garden appliance at Natufia. https://natufia.com/ I have been primarily responsible for: • Develop the idea of mechanical systems from paper to a 3D model in Solidworks. Do the necessary calculations and simulations if required • Develop the aesthetic form of the product • Design for 3D printing in order to test the design • Define the manufacturing processes for the product • Define the assembly process of the product • Develop a detailed design of the product as per the manufacturing process • Interact with the Industrial designers in the team to meet the client brief • Developing 2D drawings for manufacturing and Patenting process • Interact with the producer to make the necessary changes to the product design

$13/hr

$13/hr

Manufacturing Processes Designer

Innovative Tool Design Engineer with a proven track record of designing tools to enhance manufacturing processes. Successfully implemented new design concepts to improve tool performance and reduce pr... Read more

Innovative Tool Design Engineer with a proven track record of designing tools to enhance manufacturing processes. Successfully implemented new design concepts to improve tool performance and reduce production costs. Led a project to redesign a critical tool component, boosting production output by 15%. Adept at collaborating with cross-functional teams to optimize tool designs for enhanced functionality and usability. Skilled in creating efficient and precise tools to drive operational efficiency

$20/hr

$20/hr

Manufacturing Processes Designer

As a Mechanical Design Engineer, I am driven by a passion for revolutionizing technology, particularly in the realm of 3D printing and advanced manufacturing. My goal is to contribute significantly to... Read more

As a Mechanical Design Engineer, I am driven by a passion for revolutionizing technology, particularly in the realm of 3D printing and advanced manufacturing. My goal is to contribute significantly to the development and application of cutting-edge technologies that improve lives and shape the future of engineering. With a solid foundation in mechanical engineering and hands-on experience in optimizing manufacturing processes and being skilled in using SOLIDWORKS for innovative product design, I have been recognized for my contributions to engineering with several awards. Beyond engineering, I am fascinated by the intersection of computer science, artificial intelligence, and modern technology. I am continuously expanding my knowledge in these areas, learning and applying new skills to stay at the forefront of technological advancements. I am committed to being an effective team player, contributing valuable insights to cross-functional teams, and managing complex projects to deliver exceptional results. As I continue my journey, I aspire to be a leading contributor in the 3D printing technology landscape and to harness the power of technology to drive positive change.

$10/hr

$10/hr

Manufacturing Processes Designer

I am a dedicated 3D CAD designer with a solid foundation in Mechanical Engineering. Currently, I am pursuing my degree in Technology of Mechanical Engineering at Universitas Gadjah Mada, where I have... Read more

I am a dedicated 3D CAD designer with a solid foundation in Mechanical Engineering. Currently, I am pursuing my degree in Technology of Mechanical Engineering at Universitas Gadjah Mada, where I have developed expertise in 3D CAD modeling and parametric design. Throughout my studies, I have honed my skills in Onshape, SolidWorks, and AutoCAD, enabling me to create accurate, functional, and manufacturable designs for a variety of applications. My experience spans across designing mechanical components, product prototypes, and generating technical documentation, which has prepared me to deliver high-quality 3D models tailored to meet client specifications. During my internship at PT Adyawinsa Stamping Industries, I gained invaluable hands-on experience in CAD and CAE modeling, particularly focusing on automotive components and manufacturing processes. I was involved in designing components for the automotive industry, including 3D modeling, simulation, and process optimization. I also worked on creating detailed designs for production, ensuring that all parts met precise tolerances and were manufacturable. This internship gave me deep insight into the practical aspects of design and engineering, and I was able to leverage SolidWorks and Autodesk Inventor to optimize designs for manufacturing. In addition to practical experience, I have also obtained the Certified SolidWorks Associate (CSWA) certification, which demonstrates my proficiency in using SOLIDWORKS for creating 3D models, assemblies, and technical drawings. This certification allows me to confidently work on complex models, ensuring they meet industry standards for both design and manufacturing. My understanding of parametric modeling helps me to create flexible and easily adjustable designs, which is critical for meeting client requirements and ensuring manufacturability. My academic background includes coursework in various relevant subjects, such as CAD, CAE, Reverse Engineering, and Manufacturing Processes. These courses have provided me with a comprehensive understanding of design principles, as well as the ability to apply theoretical knowledge to real-world projects. In particular, Reverse Engineering has equipped me with the skills to analyze existing products and create accurate CAD models based on physical objects, which is essential for product development and prototyping. I have also achieved a 3.50 GPA (IPK), reflecting my commitment to excellence in both my academic and practical work. This strong academic foundation, combined with my internship experience and certification, has helped me develop a well-rounded skill set that I bring to every project I undertake. I am focused on delivering designs that not only meet functional specifications but are also optimized for the production process. I specialize in creating 3D CAD models for a variety of applications, including mechanical components, prototypes, and engineering assemblies. I ensure that all designs are created with a clear understanding of the required tolerances, material properties, and production methods. I work closely with clients to understand their specific needs and ensure that my designs align with their goals, whether for 3D printing, CNC machining, or other production methods. My design process involves creating parametric models, performing design validation, and generating technical drawings with precise dimensions and tolerances for manufacturing. Using Onshape's cloud-based platform, I can collaborate efficiently with clients, ensuring that the design process is transparent and that feedback can be quickly incorporated into the final product. This collaboration allows for real-time changes, reducing the risk of miscommunication and ensuring the design meets the client's expectations. I also provide multiple revisions to ensure the final design is aligned with the client's needs and goals. My services are particularly well-suited for students, professionals, and small businesses looking for high-quality 3D CAD design. Whether you need a mechanical part, product prototype, or engineering simulation, I am committed to delivering accurate, cost-effective, and manufacturable designs. My goal is to provide a seamless experience from the initial concept through to the final design, ensuring that the project is completed on time and within budget. With a strong foundation in both the theoretical and practical aspects of Mechanical Engineering and 3D CAD design, I am well-equipped to tackle a wide range of projects. My passion for design and problem-solving drives me to continuously improve my skills and stay up-to-date with the latest developments in the industry. I am excited to bring my expertise and dedication to every project I work on, helping clients achieve their design goals with precision and professionalism.I am a dedicated 3D CAD designer with a solid foundation in Mechanical Engineering. Currently, I am pursuing my degree in Technology of Mechanical

$15/hr

$15/hr

Manufacturing Processes Designer

3D Artist & Mechanical Engineer | Expert in Product Design & 3D Visualization I am a skilled 3D artist and mechanical engineer with expertise in product design, industrial modeling, and 3D visualizat... Read more

3D Artist & Mechanical Engineer | Expert in Product Design & 3D Visualization I am a skilled 3D artist and mechanical engineer with expertise in product design, industrial modeling, and 3D visualization. With a strong background in both engineering principles and artistic creativity, I create highly detailed, functional, and visually appealing 3D models tailored for manufacturing, prototyping, and presentation purposes. What I Offer: ✔ 3D CAD Modeling – Precise and optimized models for manufacturing and prototyping (STL, STEP, IGES). ✔ Product Design & Development – From concept sketches to fully engineered designs. ✔ 3D Rendering & Visualization – High-quality photorealistic renders for presentations, marketing, and investor pitches. ✔ Mechanical & Industrial Design – Functional designs for consumer products, machines, and custom mechanical parts. ✔ 3D Printing & CNC-ready Models – Optimized files for manufacturing processes. I am proficient in SolidWorks, Fusion 360, AutoCAD, Blender, and KeyShot, ensuring high-quality outputs that align with both aesthetic and functional requirements. Whether you need a concept brought to life, a mechanical component designed, or a stunning product visualization, I am here to deliver exceptional results. Let’s bring your ideas to reality! Feel free to reach out, and let’s discuss your project.

$10/hr

$10/hr

Manufacturing Processes Designer

Last updated: Nov 13, 2025

Manufacturing processes are the steps through which raw materials are transformed into a final product that brings together a wide variety of disciplines and fields. Depending on the industry in which the manufacturing is taking place, there is a wide variety of ways to manufacture a product. Sometimes this means casting, imaging, or molding, as well as a wide variety of other styles. No matter what sort of manufacturing processes your company needs to undergo in order to produce your product, you can find it here at Cad Crowd. Cad Crowd offers a wide variety of manufacturing process freelancers who are skilled in a number of different types of processes, from machining to welding and beyond.

Manufacturing process freelancers at Cad Crowd are skilled in many disciplines, one of which is casting, which includes the following types of casting: die, centrifugal, investment, permanent mold, resin, sand, and vacuum molding. Imaging and coating skills that our freelancers possess include laser engraving, chemical vapor deposition, inkjet printing, plating, thermal spraying, and plating.

You can also work with experts who know the ins and outs of molding, including plastic molding through injecting, blow molding, dip molding, thermoforming, lamination, foam, and vacuum plug assisted molding. When you need to form different shapes, you can do so through our freelancers with expertise in end tube forming, forging, rolling, extrusion, shearing, piercing, stamping, bending, cold sizing, embossing, drawing, curling, hydroforming, and explosive forming as well as many others.

Our machining freelancers can handle a huge variety of skills, including milling, turning, planing, honing and sharpening, finishing and industrial finishing, drilling, teaming, broaching, shaping, electron beam machining, chemical shaping, grinding, and more. Joining manufacturing including welding, resistance, projection welding, seams, sintering, adhesive bonding, soldering, brazing, and press fitting can also be accomplished. As you can see, there are a variety of skills the manufacturing processes freelancers at Cad Crowd are able to handle, and these are only a few of the disciplines and sub-disciplines that we can help you take care of in your unique project.

At Cad Crowd, we are dedicated to providing you with only the best of the best of freelance manufacturing processes experts. These experts have all been heavily vetted in order to provide you with services that are unmatched by any other freelancing service. To find a freelance manufacturing processes expert, you can browse their portfolios to find the one whose work impresses you most, or you can let us pair you up with who we think is best for the job. You can remain in contact with the freelancer you are working with during the duration of the job to ensure that things are going the way you want. You can also be sure that you are going to get the project returned to you both on time and within budget. Contact Cad Crowd today in order to get your personalized, free, and no-obligation quote on your project so you can get started on it right away.